How is Mitsui Chemicals AURUM™ used in the Semiconductor Industry?

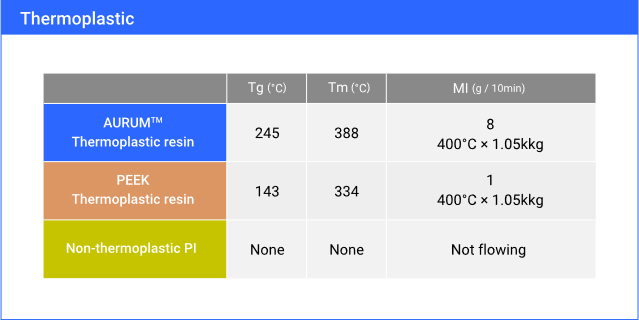

The semiconductor industry widely uses Mitsui Chemical AURUM™ Thermoplastic Polyimide Material because of its superior heat resistance, mechanical strength, and electrical insulating qualities. Excellent performance makes Mitsui Chemicals' AURUM™ TPI a crucial component in producing cutting-edge semiconductor devices.

PROPERTIES OF AURUM™

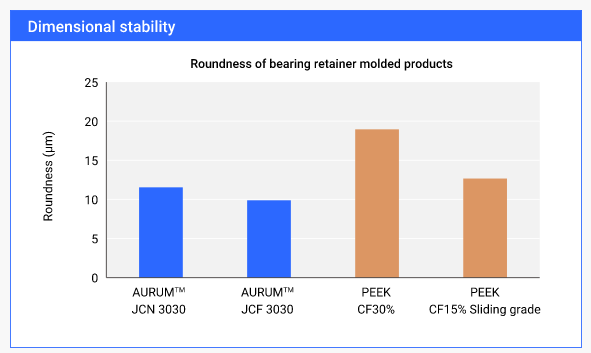

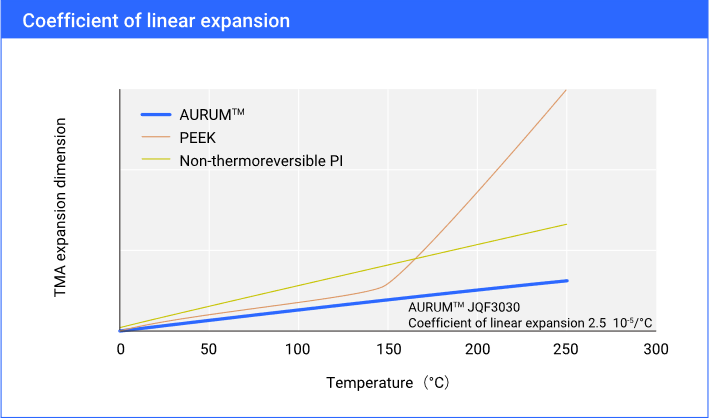

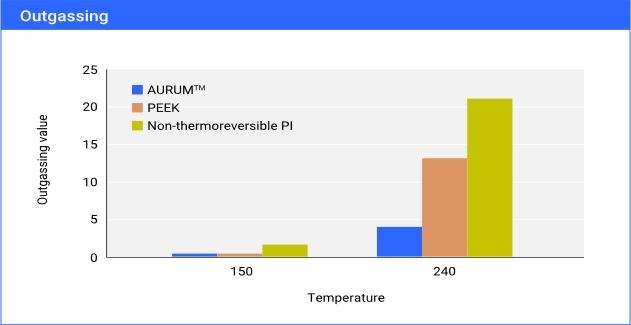

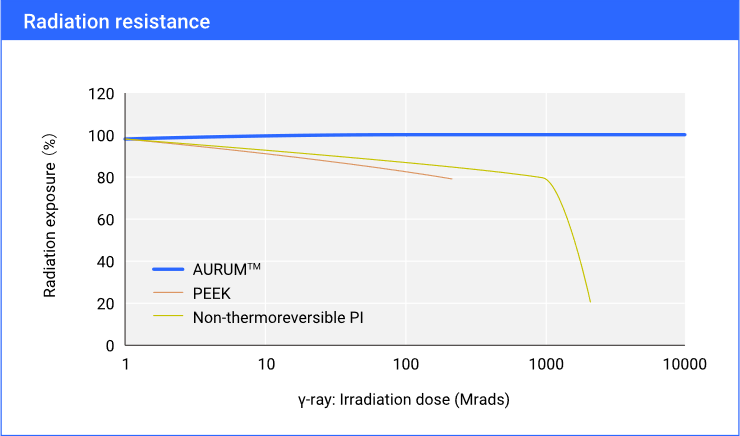

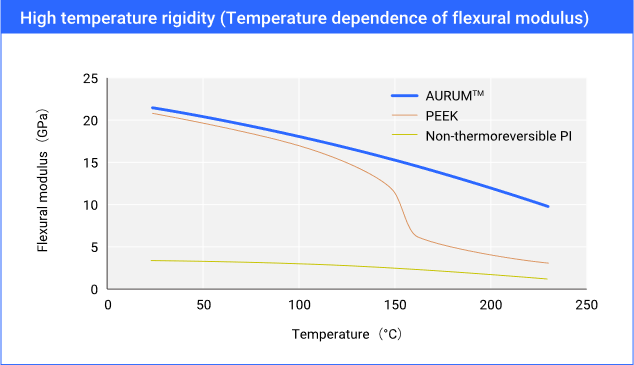

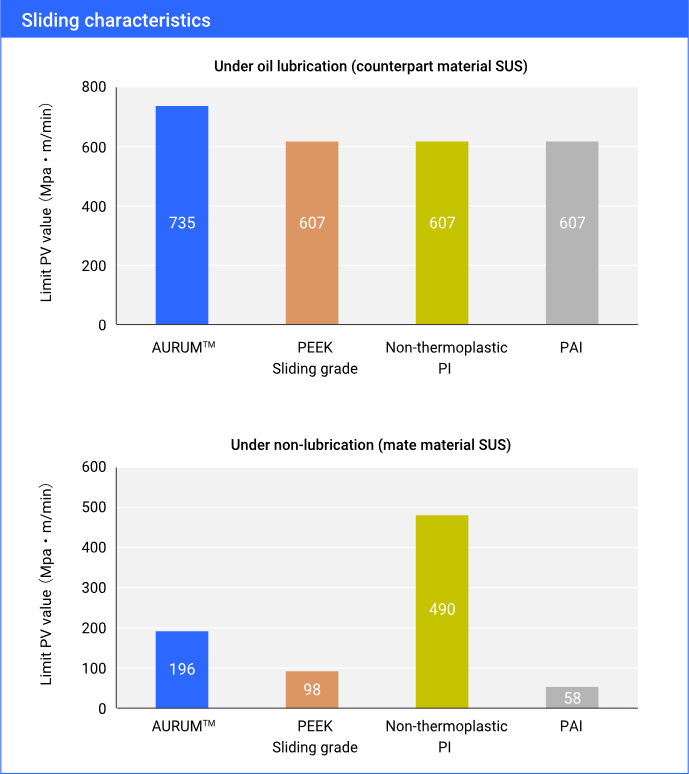

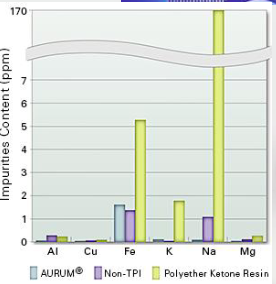

AURUM™ distinctive physical properties include radiation resistance, a low coefficient of linear thermal expansion equal to aluminum; it has a High-temperature stiffness Tg 245°C (473°F), which means it is used in a harsh environment; it has a high residual elasticity at -196°C (or lower), it is thermoplastic, signifying it can be injection molded, it has sliding properties compared to PEEK and other HPPs, also, with the highest critical PV value of any thermoplastic resin. AURUM™ has low outgassing at a high temperature and fewer impurities (e.g., metals) than other HPPs.

AURUM™ TPI can be used in the semiconductor industry for managing and manufacturing semiconductor wafers due to AURUM™'s physical properties, for example, its low outgas property. AURUM™ is used for making connectors, sockets, and more components used in the semiconductor industry.

Along with high electrical breakdown voltage, low permittivity, and ease of application either by extrusion or powder coating, AURUM™ TPI is the perfect insulator, even at very thin layers.

Due to AURUM™ electrical insulation qualities, it can be used to manufacture probe cards, which are used to make electrical connectors. Furthermore, its electrical properties make it suitable for wire insulation in semiconductor devices. Also, AURUM™'s elasticity, thermal stability, and high dielectric strength make it applicable for producing thin film dielectric materials.

BARplast LLC, part of the BIEGLO group, offers Mitsui Chemicals' thermoplastic polyimide powder AURUM™. This TPI is the only Polymer with a Tg of 245 °C (473°F) and exhibits high-temperature stiffness properties. Compared to other thermoplastic resins, AURUM™ generates less outgassing and less contamination (suitable for PCBs & sensors). AURUM™'s injection-molding and extruded ability makes it ideal for large-quantity applications.

TPI AURUM™, a moldable polyimide, combines excellent thermal resistance and distortion temperature with high cleanliness and low outgassing properties, which is essential for electronics applications.

Along with high electrical breakdown voltage, low permittivity, and easy application either by extrusion or powder coating, AURUM™ TPI is the perfect insulator, even at fragile layers.

Polymers Application in the Semiconductor Industry:

CMP Rings

Heater Coil Spacer

Lift Pin Holder

Wafer holder

Retaining/Clamp Ring

Mechanical Screw

Die Bonding Tool

Test Socket

End Effector Gripper

Handling Device

Cable insulation

Glass Panel Supports

Etch Chamber Parts / Ring

Requirements for Materials

► Good wear/abrasion resistance

► Low friction

► Low material removal rate

► Low outgassing

► Thermal stability

► Dimensional stability

► Low etch rate – chemical stability

► Less brittle than ceramics

► Good flexural modulus

► High dielectric strength or ESD

► Reasonable pricing

► Availability / Multiple channels

DISCLAIMER: This information on this website is only intended to be general information for use of our customers and interested parties. This information does not replace written law or regulations, nor does it replace professional advice regarding specific applications of goods mentioned.