About the author

John Biesterfeld has several decades of experience in the Polymer industry. He worked in marketing, sales and business leadership in France, USA, the Netherlands and Germany.He is the founder of the BIEGLO-group that specializes in the marketing and sales of High-Performance Polymers in Europe and North America. BARplast LLC is part of the BIEGLO-group.

John Biesterfeld, President of BARplast LLC

We asked ChatGPT “What questions people have about AURUM® Thermoplastic Polyimide”?

...here is the outcome

1. What is AURUM® thermoplastic polyimide, and what are its main characteristics?

AURUM® is a polyimide resin with outstanding properties. Its thermoplasticity is suitable for injection molding and extrusion. It has unparalleled super-high heat resistance and excellent mechanical, sliding, and electrical properties. Mitsui Chemicals itself has developed this TPI and is a globally unique resin.

Properties

► Super-high heat resistance: Usable at up to 240°C (464°F) (glass transition temperature: 250°C (482°F)

► Satisfactory sliding properties: A low, stable coefficient of friction and low friction wear

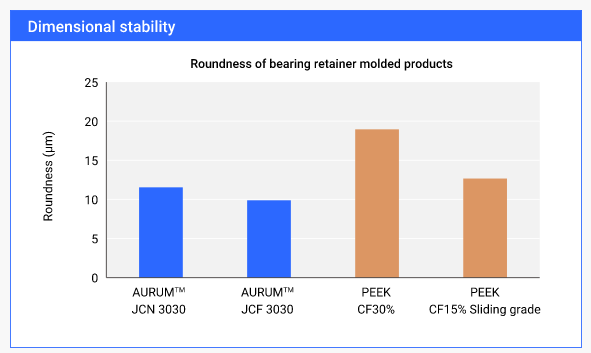

► Outstanding dimensional stability: Stable coefficient of expansion and satisfactory creep characteristics

► Exceptionally clean properties: Trace amounts of outgassing and metallic impurities

2. How does AURUM® compare to traditional polyimides in terms of processability and performance?

AURUM® challenges the conventional wisdom that polyimides offer exceptional high-heat performance but are difficult to process. AURUM® a thermoplastic resin, can injection mold high-precision materials, In contrast to traditional thermosetting polyimide, which parts are often machined from stock shapes or thin sheets.

Furthermore, AURUM® has a glass transition temperature (Tg) of 245°C (473°F) which is 100°C (212°F) higher than PEEK resin 143°C (289,4°F) and exhibits a stable coefficient of thermal expansion at temperatures up to its Tg. In addition, AURUM® has the highest glass transition temperature of any thermoplastic resin.

3. What industries of applications can benefit from using AURUM® thermoplastic polyimide?

A lot of high technology fields, including the aerospace, microelectronics, automobile and medical device industries, extensively use AURUM®

Here is a list of some applications of AURUM® in automotive applications:

► Seal rings, thrust washers & bearings for transmission

► Turbo Charger abradable seal

► Cable insulation for very high and low-temperature environments

► Thin Film in electronic devices

► Trays for semiconductor testing

The high- & low-temperature resistance of AURUM® Thermoplastic Polyimide has led to the developing of industrial oil seals, impellers, hydrogen seals, and demanding wire coating applications in the aerospace industry.

4. What is AURUM® 's key thermal and mechanical properties that make it stand out?

AURUM® has a high Tg 245℃ (473°F), which makes AURUM® a Providing superior temperature stiffness at 150℃ (302°F) and higher than PEEK.

► Stable coefficient of expansion at up to 245℃ (473°F)

► Better heat resistance and dimensional stability than PEEK

► Superior creep resistance even at a high temp

AURUM® is thermoplastic:

You can fill it with additives to control its coefficient of expansion.

Can undergo injection molding and get rid of the need for cutting machining.

Additionally, AURUM® has the highest critical PV value of any thermoplastic resin. (in a non-lubricated / oil-lubricated condition sliding) AURUM® has lower outgas properties than PEEK and non-thermoplastic PI at high-temperature ranges. Furthermore, AURUM® exhibits better radiation resistance than PEEK and non-thermoplastic PI (reduction in tensile strength is minimal). Lastly, AURUM® has half the shrinkage factor of PEEK (AURUM® :0.7%, PEEK:1.5-2.0%) and produces superior dimensional accuracy in fiber-reinforced grade products.

5. Can you explain the unique chemical structure of AURUM® and its impact on its properties?

AURUM® has a polyimide backbone chemical structure, which makes AURUM® highly chemical resistant against gasoline, various lubricants, aviation fuels, and cleaning agents.

6. What processing methods are used to fabricate components from AURUM® thermoplastic polyimide?

AURUM® a thermoplastic resin is capable of being injection molded to create high-precision parts.

AURUM® PL450C and other grades have the ability to undergo extrusion to produce film or sheet.

7. Are there any challenges associated with using AURUM® in a specific environment?

Yes, this material has specific challenges:

► High Cost/kg

► High-temperature injection molding machine 400 - 420°C (752°F-788°F) is required

► Post-cleaning process in injection molding machine

8. Why does AURUM® outperform PAI and PEEK when designing parts where dimensional stability and thermal expansion are key?

9. Please give real-world examples of successful applications where AURUM® thermoplastic polyimide has replaced PEEK.

The AURUM® Mitsui websites mention several case studies at https://jp.mitsuichemic®als.com/en/special/AURUM®/case_studies/#case1

These following highlight applications where AURUM can replace PEEK

Applications | Advantages with AURUM® | Recommended grades |

| Thrust washers for transmissions | ►Effects of weight reduction: approx. 60% (compared with SUS) ►It is suitable for use in demanding sliding applications (use for large-diameter washers) | JCL 3030 |

| Seal rings for transmissions | ►Used in sliding applications with harsh environments (in environments of 150℃ (302°F)and higher) ►Gap joint shape flexibility (thermoplastic resin) | JCF 3030, J-3124 |

| Resins for CFRP | CFRP with excellent high-temperature properties is capable of being applied to aircraft components and materials | PD450, PD500A; PL450C, PL500A |

| Electric wire coating | Possesses heat and low-temp. resistance, electrical properties comparable to PAI (polyamide-imide), and enables extrusion coating | PD450, PD500A |

10. Can you dissolve AURUM® powder in water or solvent?

Generally, Polyimides are soluble in organic solvents, such as tetrahydrofuran (THF), dimethylformamide (DMF), dimethylacetamide (DMAc), N-methyl pyrrolidone (NMP) methylene chloride, and cyclohexanone.

11. What are the advantages and disadvantages of AURUM® compared to Vespel?

vs thermosetting PI (e.g., Vespel) | vs PEEK (e.g., Victrex-Peek) | vs PAI (e.g., Torlon) | vs PEI (e.g., Ultem) |

| ►Injection molding is applicable ►Vespel needs machining | ►Stable stiffness up to 245℃ ►Stiffness of PEEK drops at its Tg (143 ℃) | ►No need of post-processing ►Torlon must be annealed for long time | ►Higher Tg and better chemical resistance |

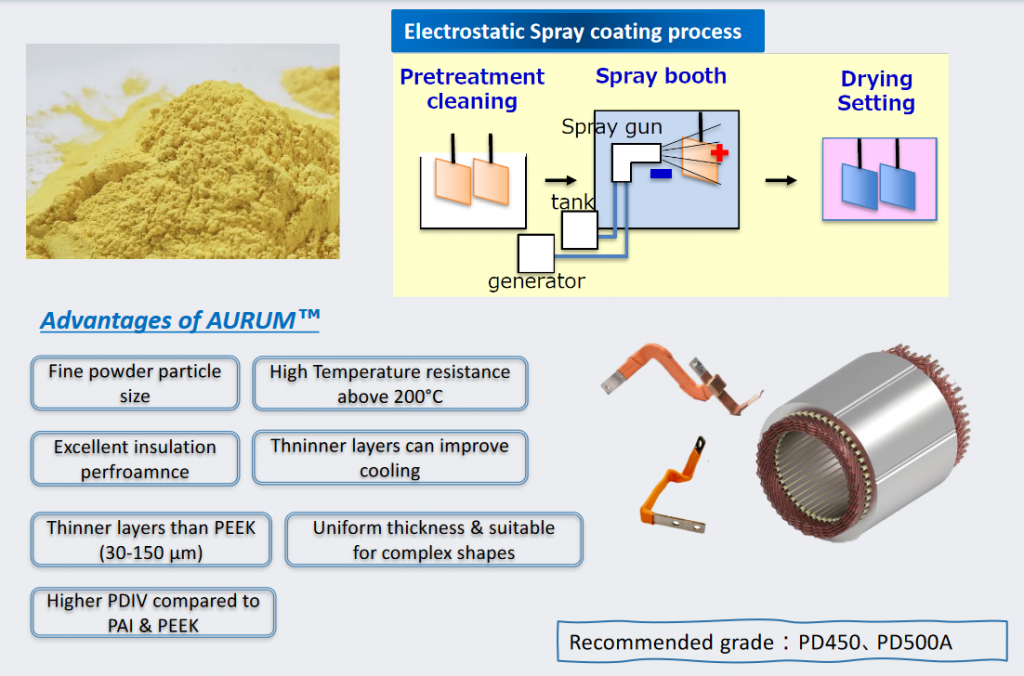

12. Can AURUM® be used for coating metal, and how can it be applied?

AURUM® finds application in insulation Coating for electric motors, hairpin Stator, and busbars (see below for more details).

You can process AURUM® through electrostatic powder, extrusion, and spray coating methods

It has excellent adhesion to copper, steel, and aluminium metals.

AURUM® 's coefficient of thermal expansion is similar to that of Aluminium.

Due of its purity, AURUM® forms fewer pin-wholes than any other thermoplastic polymer.

DISCLAIMER: This information on this website is only intended to be general information for use of our customers and interested parties. This information does not replace written law or regulations, nor does it replace professional advice regarding specific applications of goods mentioned.